A Comprehensive Guide to Custom Cut Metal Signs: From Design to Durability

Related Articles: A Comprehensive Guide to Custom Cut Metal Signs: From Design to Durability

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to A Comprehensive Guide to Custom Cut Metal Signs: From Design to Durability. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A Comprehensive Guide to Custom Cut Metal Signs: From Design to Durability

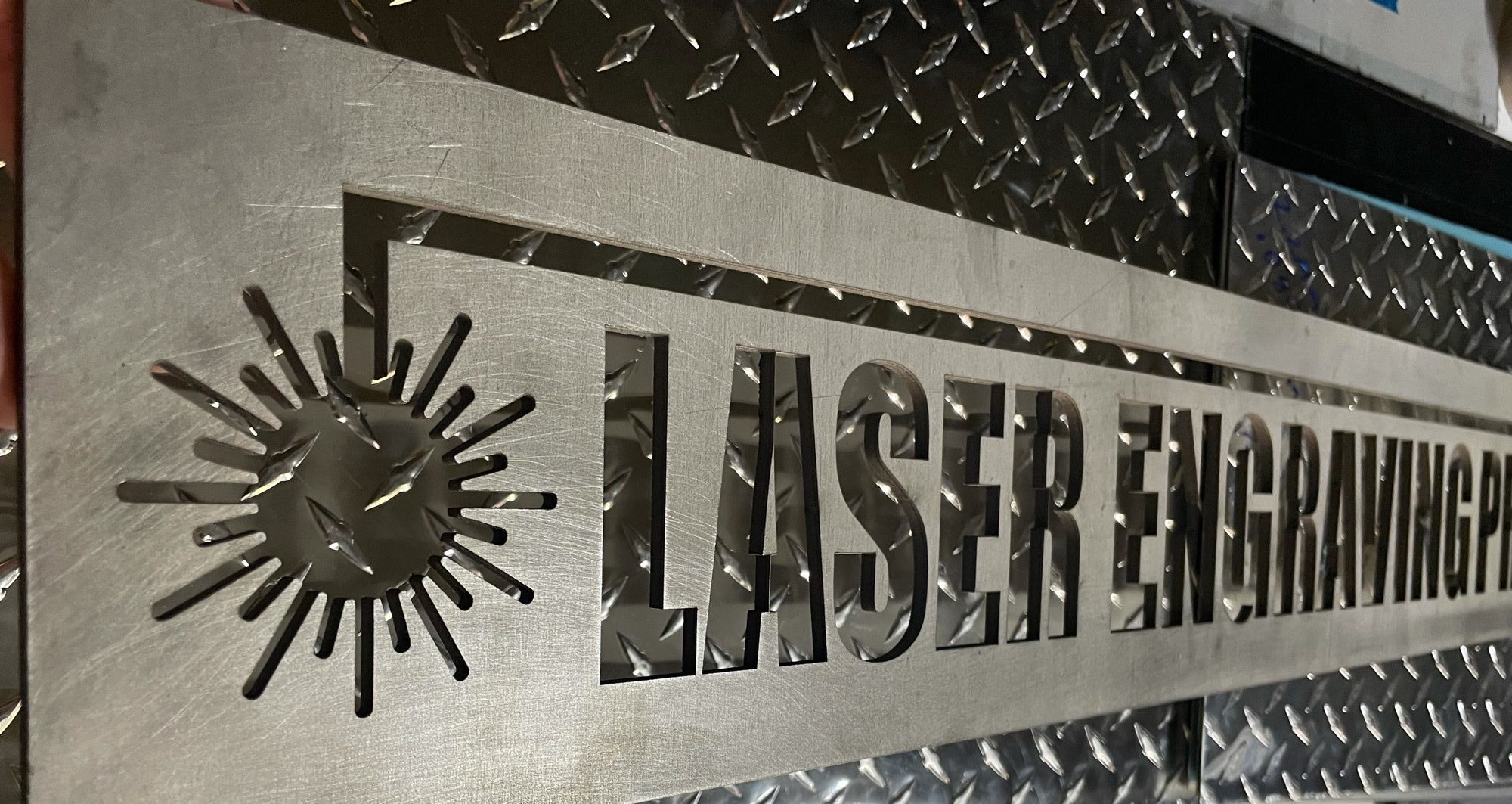

Custom cut metal signs have become a ubiquitous fixture in the modern landscape, adorning storefronts, guiding visitors, and adding a touch of industrial chic to homes and businesses. Their versatility and durability make them an ideal choice for a variety of applications, ranging from simple directional signs to elaborate, artistic pieces. This article delves into the world of custom cut metal signs, exploring their design, fabrication, applications, and the benefits they offer.

Design and Fabrication:

The process of creating a custom cut metal sign begins with design. Clients work closely with sign manufacturers to translate their vision into a tangible product. This involves selecting the desired metal, size, shape, and design elements. The most common metals used for custom cut signs include:

- Aluminum: Lightweight, corrosion-resistant, and available in a wide range of colors, aluminum is a popular choice for both indoor and outdoor signs.

- Steel: Durable and robust, steel is often used for large, heavy-duty signs, particularly those exposed to harsh weather conditions.

- Brass: Known for its warm, lustrous finish, brass is frequently used for elegant, decorative signs.

- Copper: Copper’s unique patina and inherent resistance to corrosion make it a desirable choice for signs that will weather naturally over time.

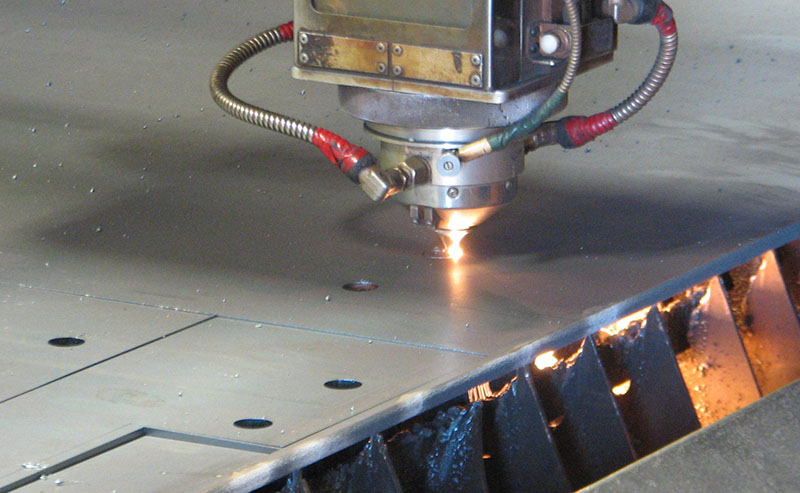

Once the design is finalized, the sign is fabricated using various techniques, including:

- Laser Cutting: A highly precise and efficient method that uses a focused laser beam to cut intricate designs into the metal.

- Waterjet Cutting: A versatile technique that uses a high-pressure stream of water mixed with an abrasive material to cut through a variety of materials, including metal.

- Plasma Cutting: A thermal cutting process that uses a high-temperature plasma arc to melt and cut the metal.

- CNC Routing: A computer-controlled process that uses a rotating cutter to carve out the desired shape from the metal sheet.

The choice of fabrication method depends on the complexity of the design, the desired finish, and the materials being used.

Applications and Benefits:

Custom cut metal signs offer a wide range of applications, catering to the diverse needs of businesses, organizations, and individuals. Here are some of the most common uses:

- Business Signage: From storefront signs to directional signage within a building, custom cut metal signs provide a professional and durable way to communicate brand identity and guide customers.

- Architectural Features: Metal signs can be incorporated into building facades, creating unique visual accents and enhancing the overall aesthetic appeal.

- Public Art: Custom cut metal signs can be transformed into artistic expressions, adding a touch of beauty and personality to public spaces.

- Memorial Plaques: Durable and weather-resistant, metal signs are ideal for creating lasting memorials to commemorate individuals, events, or historical landmarks.

- Wayfinding Signage: Metal signs are commonly used in parks, campuses, and other public areas to guide visitors and enhance accessibility.

- Home Decor: Custom cut metal signs can add a unique touch to home interiors and exteriors, showcasing personal style and adding a decorative element.

The benefits of using custom cut metal signs extend beyond their aesthetic appeal. Here are some key advantages:

- Durability: Metal signs are highly resistant to wear, tear, and weather damage, ensuring long-lasting performance.

- Versatility: The ability to customize size, shape, and design allows for endless possibilities in creating unique and functional signs.

- Customization: Clients have complete control over the design, ensuring the sign perfectly reflects their brand, message, or personal style.

- Visibility: Metal signs are visually striking and can be designed to stand out from their surroundings, attracting attention and conveying information effectively.

- Professionalism: Custom cut metal signs convey a sense of professionalism and sophistication, enhancing the image of businesses and organizations.

- Sustainability: Metal is a recyclable material, making custom cut metal signs an environmentally responsible choice.

FAQs about Custom Cut Metal Signs:

Q: What is the typical cost of a custom cut metal sign?

A: The cost of a custom cut metal sign varies depending on factors such as size, complexity, materials used, and fabrication techniques. It is advisable to contact multiple sign manufacturers to obtain quotes and compare prices.

Q: How long does it take to create a custom cut metal sign?

A: The production time for a custom cut metal sign depends on the complexity of the design and the workload of the sign manufacturer. Typical lead times range from a few weeks to a few months.

Q: What types of finishes are available for custom cut metal signs?

A: A wide range of finishes are available for custom cut metal signs, including powder coating, painting, anodizing, and natural weathering. The choice of finish depends on the desired aesthetic and the intended use of the sign.

Q: How do I care for a custom cut metal sign?

A: Metal signs generally require minimal maintenance. Regular cleaning with mild soap and water is sufficient to keep them looking their best. For signs exposed to harsh weather conditions, consider applying a protective sealant to prevent corrosion.

Q: Are custom cut metal signs suitable for indoor use?

A: Yes, custom cut metal signs are suitable for both indoor and outdoor use. However, consider the environment and the specific metal used when making this decision.

Tips for Designing Custom Cut Metal Signs:

- Define your purpose: Clearly identify the message you want to convey and the audience you are targeting.

- Keep it simple: A clean, uncluttered design is easier to read and understand.

- Choose the right font: Select a font that is legible and complements the overall design.

- Use contrasting colors: Ensure the text and background colors provide sufficient contrast for optimal visibility.

- Consider the environment: Take into account the surrounding environment when selecting materials and colors.

- Get professional help: Consult with a sign manufacturer for guidance on design, materials, and fabrication techniques.

Conclusion:

Custom cut metal signs offer a compelling blend of durability, versatility, and aesthetic appeal, making them a valuable asset for businesses, organizations, and individuals. By carefully considering design, materials, and fabrication techniques, clients can create unique and impactful signs that effectively communicate their message, enhance brand identity, and add a touch of elegance to any environment. The enduring nature of custom cut metal signs ensures they will continue to be a prominent feature in the landscape for years to come.

Closure

Thus, we hope this article has provided valuable insights into A Comprehensive Guide to Custom Cut Metal Signs: From Design to Durability. We appreciate your attention to our article. See you in our next article!